| Message |

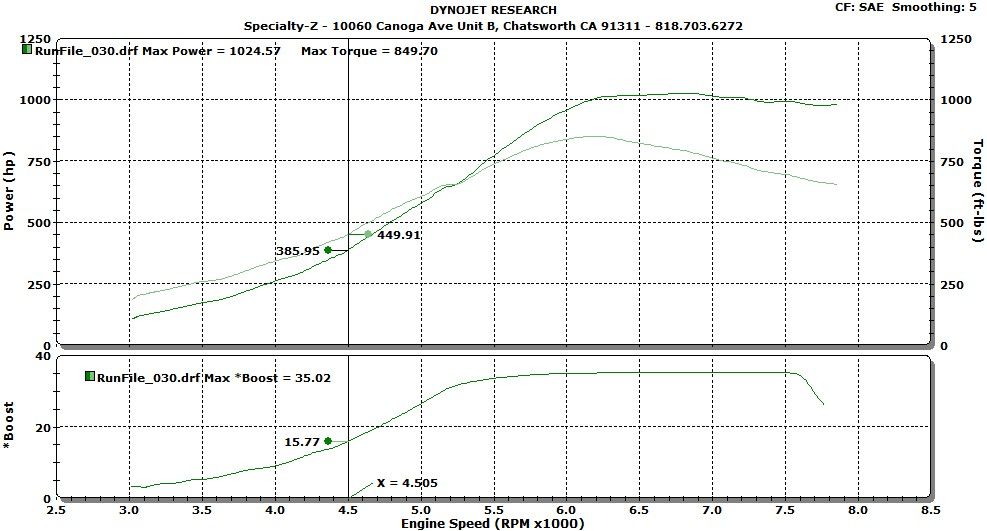

If you look at Steve's dyno chart, you will notice some instability in the power between 5100 and 5300RPM.

The power at the wheels where this starts to occur is about 600 RWHP.

If you take the driveline loss of the auto (about 20%), we assume 720 crank HP where the instability occurs.

The boost level where the instability starts is about 30 PSI.

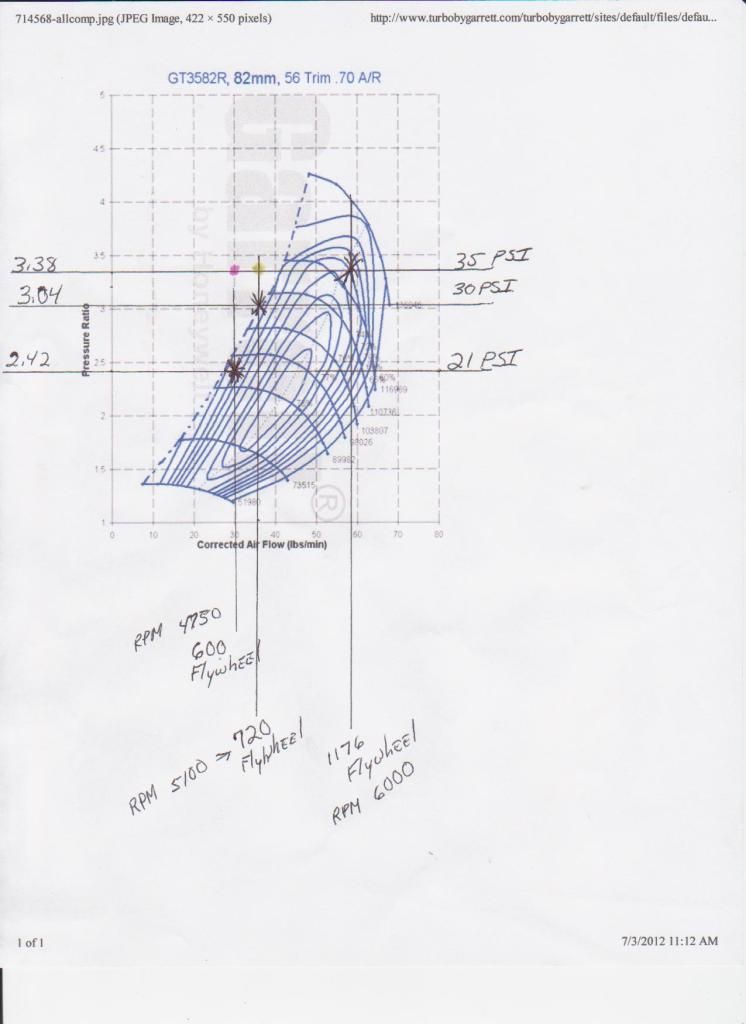

If you look at the compressor map for the turbos Steve is running, you will find his dyno hitting the surge line of the turbo at about 30 PSI boost.

The way to locate this area on the compressor map is as follows......

The compressor shows lbs of air at the bottom, 1 lb of air for every 10 HP is the general rule, So 100HP is 10 lbs of air.

Take the HP for the problem area (720 HP), divide by 2 since 2 turbos are being used (390) = 39 lbs corrected air flow.

Take the boost pressure (30 lbs), find the pressure ratio 30 PSI+14.7/14.7 = 3.04 pressure ratio If you look at the chart where the pressure ratio of 3.04 and the corrected air flow of 39 lbs cross, you will see Steve's set up crosses the surge line.

The higher the RPM the engine rev's, the the more flow the engine provides, at lower RPM the engine has more restriction.

If the engine could flow more air at lower RPM, the pressure would be lower from less resistance.

Pressure is simply the measurement of resistance. So if we are at the surge line at 5100 RPM at 30 PSI boost, rev the engine to 7000+ making 35PSI boost while keeping the throttle wide open, then have a auto trans shift bringing the engine RPM down to 5100 RPM or less, what will happen?

We have now put the engine in a RPM area that created 30 PSI pressure when the turbo was flowing 36 lbs corrected Air flow, But now the turbo is flowing about 60 lbs corrected air flow at 35 PSI!

The resistance of the engine at 5100 RPM can not flow 35 PSI at 60 lbs flow, so the pressure is going to spike and stall the compressor.

Even without a pressure spike (and it will) the boost pressure alone maintained at 35 PSI would put you on the green dot at 5100 RPM, or the pink dot at 4750 RPM.

Because the turbo is flowing double the amount of air at 7000 than it was at 4750, you can expect the pressure spike to be significant and the turbo will stall as Steve experienced.

A ported cover is designed to relieve pressure spikes and recirculate the flow the engine can not consume, the amount Steve's set up goes into surge causes me to think he might need more than just the ported covers at full boost.

|

|